Advancing the (Electrotechnical) Industry: Leveraging ETIM-MC and 3D Models for Unprecedented Benefits

In an age marked by technological breakthroughs, industries are continually exploring innovative ways to enhance efficiency, collaboration, and customer satisfaction. For the electrotechnical sector, two transformative tools are shaping the landscape: the adoption of ETIM Modelling Classes and the integration of 3D models for each component.

Profound advantages of embracing ETIM-MC

Here we delve into the profound advantages that wholesalers and manufacturers of electrotechnical components can harness by embracing ETIM Modelling Classes and the integration of 3D models for each component in tandem.

After the creation of the basic ETIM classification around 2000, the model continues to be successfully adopted by numerous manufacturers, wholesalers and users to exchange product characteristics. ETIM has become the multilingual industry standard in certain industries for many countries around the world.

When working with this product data, there were increasing requirements of the data for use in calculation and CAD software, requiring an additional set of data. In order not to interfere with the existing use of the classification model, it was decided to design this entirely outside the existing classification set, but still keep a connection to the basic product classes and characteristics.

In addition to initial application by the electrical and installation industry in particular, ETIM has now also been embraced by the maritime and construction industry, among others, resulting in an increased need for BIM/3D data. Within the 3D software, parametric design can be realised as soon as ETIM MC is provided, also enabling e.g. material outlines and light calculations.

Precision in Product Classification by Modelling Classes

Foundation: ETIM Classification

ETIM Classes offer a structured framework for classifying electrotechnical products. Wholesalers and manufacturers can benefit from a standardized taxonomy that promotes clear communication, minimizes confusion, and ensures seamless collaboration throughout the supply chain. This precision in classification simplifies product identification, streamlines inventory management, and creates an environment of efficient teamwork.

Addition: ETIM Modelling Classes

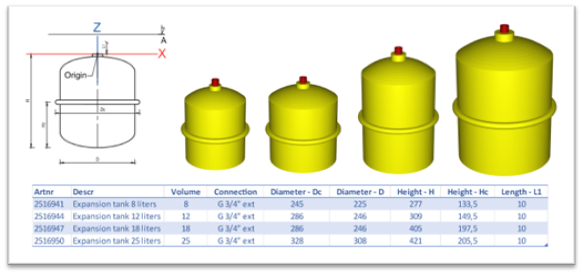

The ETIM International team has extended the existing classification with the Modelling Classes, linked to every suitable ETIM class. These have their own characteristics that are linked to the named parameters via an MC-drawing, which gives insight in the used parameters. An MC-drawing is an indication of the basic characteristics of a given product. Thus, every application and user of the classification knows which dimension the parameter has in the 3D model.

The video below provides a general explanation of ETIM-MC.

Supplemented by general product data, depending on the software in which calculations or drawings are made, the information provider can provide end users with all the necessary data.

Features and drawings of ETIM-MC

Practical usage of ETIM-MC

Enhanced Product Understanding and Decision-Making

By adopting ETIM-MC, manufacturers can provide detailed, standardized attributes for each component. When coupled with 3D-models or CAD models, these attributes come to life, enabling wholesalers and buyers to make informed decisions based on visual and technical specifications. This comprehensive information not only reduces the risk of errors but also empowers stakeholders to choose the right components with confidence.

Functions of ETIM-MC in the product lifecycle

3D models provide a tangible advantage in the design and implementation phases. Manufacturers who offer 3D or CAD models of their components enable engineers and designers to integrate these models directly into their projects. This integration eliminates the need for manual modelling, reduces design errors, and accelerates time-to-market for new products. This is often called ‘parametric design’.

View ETIM and ETIM-MC classesStreamlined conversion to models

Parametric design enables conversion from product specification to a electrotechnical or BIM model, by using the provided ETIM-MC information of the manufacturer. Manufacturers can manage and distribute the ETIM MC information to datapools by using a PIM system. Specific CAD and BIM software providers can use this in their software libraries.

Efficient Communication

The combination of ETIM Modelling Classes and CAD models facilitates efficient collaboration between wholesalers, manufacturers, and clients. With standardized product data and visual representations readily available, communication becomes more effective and accurate. This synergy leads to quicker response times, minimized misunderstandings, and improved overall project outcomes.

Enhancing Customer Experience

Wholesalers who provide 3D models alongside standardized product data enhance the customer experience. Engineers and designers can accurately visualize how components fit into their projects, leading to improved decision-making and fewer design iterations. This level of convenience and accuracy translates to satisfied customers and lasting partnerships.

How to use ETIM-MC data in 3D software?

In the Netherlands, the initiative has been taken to make the products provided with parametric ETIM MC available via the UOB, Universal Object Library. Universal 3D models of many model classes are already available for various CAD applications.

Internationally, Trimble Connect/MEPcontent is an example of a provider of product information enriched with ETIM MC. In CAD Software such as Stabicad, libraries can be used. This allows for instance a lighting plan or cable tray system to be designed with all the advantages concerning parametric design.

Global Market Expansion

The adoption of ETIM Modelling Classes and 3D models opens doors to new markets on a global scale. Manufacturers can align their product data and models with international standards, making it easier to enter diverse markets and cater to a broader customer base. This expansion potential can drive business growth and diversification.

Integrating 3D models within the framework of ETIM-MC streamlines data management and communication processes. This not only enhances operational efficiency but also reduces costs associated with data errors, manual modeling, and design modifications.

The synergy between standardized classification and 3D models is future-oriented. By adopting these solutions, wholesalers and manufacturers position themselves at the forefront of industry innovation. They can easily adapt to evolving trends, technologies, and customer expectations, ensuring sustained relevance in an ever-changing market.

Conclusion

The marriage of ETIM-MC and 3D models is a transformative step forward for the electrotechnical industryFrom precise product classification and efficient collaboration to streamlined design processes and global market access, the benefits are undeniable. Wholesalers and manufacturers who embrace this holistic approach are poised to revolutionize their operations, enhance customer satisfaction, and carve out a competitive edge in a dynamic and demanding marketplace. As the industry continues its evolution, those who harness the potential of both ETIM Modelling Classes and 3D models / CAD-models are paving the way for a future characterized by growth, innovation, and unparalleled success.